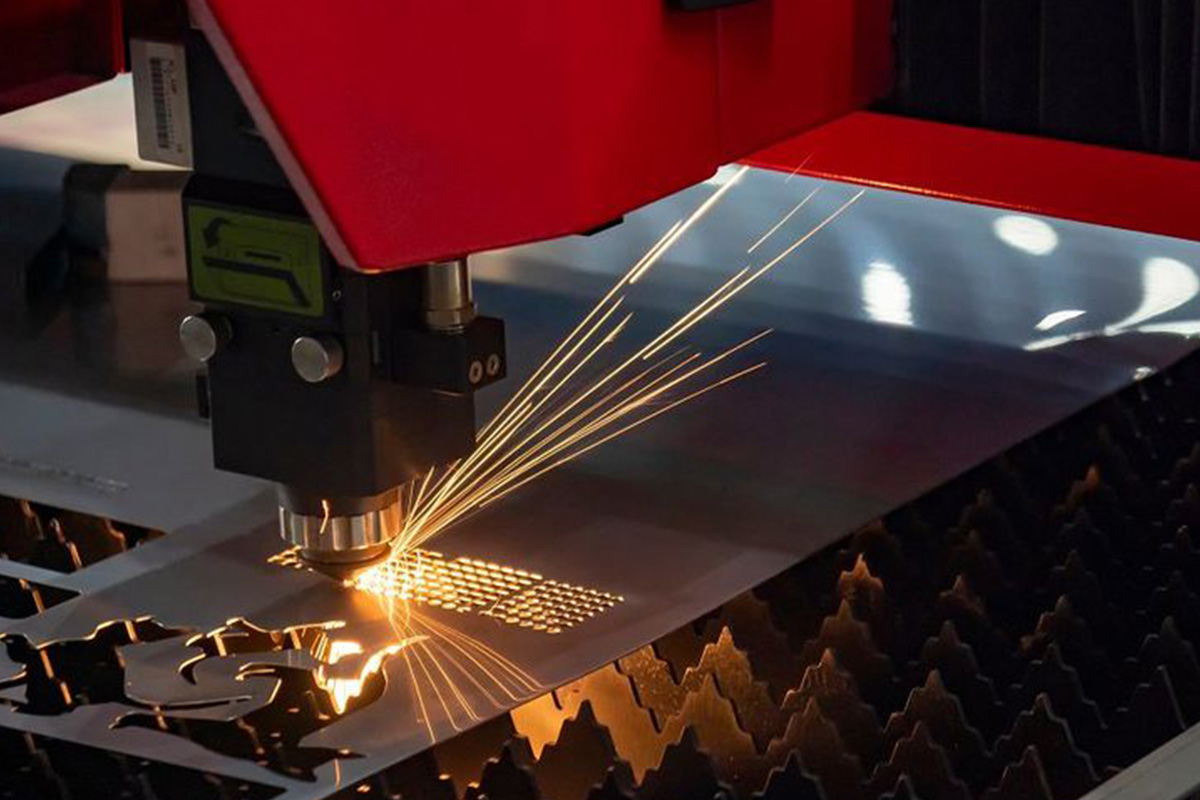

At Divine Cut Designs (DCD), we believe that great results come from the perfect blend of advanced machinery and skilled craftsmanship. Our state-of-the-art infrastructure allows us to handle projects of any scale with precision, speed, and consistency. Here’s a closer look at our core machines: